E-mail:

info@bjsecurityscreen.com

Baojiao Hardware Product Co., Ltd.

Skype£ºbaojiao863

Mobile£º0086-13623373995

Tel£º0086-0318-8093718

Msn£ºbjsecurityscreen@hotmail.com

Email£ºinfo@bjsecurityscreen.com

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

Sintered Metals¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡ Sintered Filter,Sintered Filters

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡¡

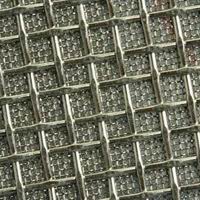

Sintered Wire Mesh Filter Screen¡¡¡¡¡¡ Sintered Wire Mesh with Perforated Metal Screen

Sintered Mesh Sintered filter

Sintered Mesh Filter Elements

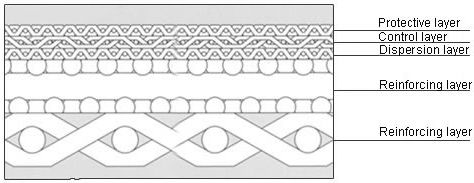

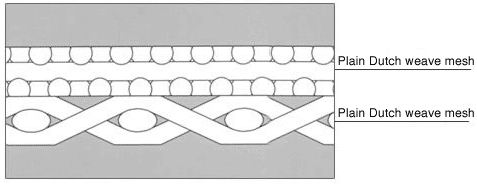

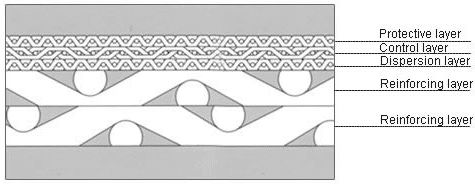

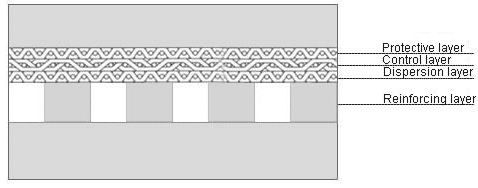

Wire mesh sintered laminates may range from a two-layer laminate of fine filter meshes to multi-layer laminate. By combining multiple layers of different mesh weaves, it is possible to design materials with specific target thickness, permeability, pore size, and mechanical strength.

Made by two layers sintered to multi-layer stainless steel mesh sintered, high mechanical strength and crushing strength, welding and assembly performance is good.

1¦Ìm to 300¦Ìm filter rating, uniformity filtration, precision filtration and finer filtration performance. When filtering, the hole size does not change.

Corrosion resistant, acid resistant, alkaline resistant, rust resistant, high temperature resistant

Easily cleaning, back-washing is more effectively, can use repeatly, very long service time

Application

Machinery industry in various hydraulic oil lubrication oil of precision filtering.

The film industry all kinds of chemical fiber filtration purification of polymer melts, oil chemical industry all kinds of high temperature, corrosion in the pharmaceutical industry, liquid filtration things of the material of filtering and washing and drying.

In powder industry in the application of gas uniformity, the steel industry in the fluidization board.

The portion of explosion protected electrical apparatus sound machine etc.

Air filtration, gas filtration, liquid filtration.